|

gongyi city Taian block making factory

|

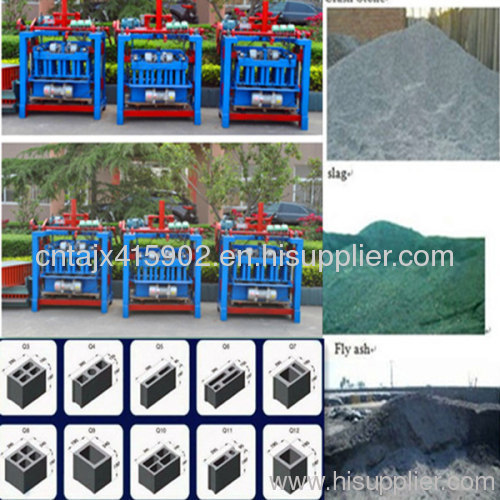

blcok making machinery

| Price: | 3000.0~5000.0 USD |

| Payment Terms: | T/T,L/C,D/A,D/P |

| Place of Origin: | Henan, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

1.easy to operate;

2.top quality;

3.molding quickly.

QMJ4-35B block machine specification :

block Size(mm) | forming blocks (pcs) | molding cycle | Capacity/8hours |

390×190×190 | 4 | 35 | 2000-2400 |

390×240×190 | 3 | 35 | 1500-1800 |

390×150×190 | 5 | 35 | 2500-3000 |

390×120×190 | 6 | 35 | 3000-3600 |

240×115×90 | 9 | 35 | 4500-5400 |

240 ×115×53 | 21 | 35 | 10500-12600 |

Advantages:

The machine has the advantage of producing high strength block, pile up neatly in short time, can save cement 5-10%, accuracy size, angular regularity. Using this machine is less investment, adapt to all kinds of aggregate, give full play to the advantages of using local materials, is best choice for individual, partnerships and construction unit production.

Routine inspection and maintenance:

Inspection:1.vertical with or without sleeve column2.whether the positioned under the mold box spring compression rod high degree of consistency

3. Whether the screw loose gear crank4.Vibrator screw loose, because two 2.2kw, power, regular inspection

5.Check whether the electrical line failure

Maintenance:1.Daily pre-construction, oil fill within the sleeve should ensure that sleeve lubrication2.Gear oil should be replaced once every 2 months3. Work should be cleaning head, the residual material on the mold box4.Vibrator work 300 hours each, filling oil should be replaced, work 800 hours should replace the bearing

The machine has the advantage of producing high strength block, pile up neatly in short time, can save cement 5-10%, accuracy size, angular regularity. Using this machine is less investment, adapt to all kinds of aggregate, give full play to the advantages of using local materials, is best choice for individual, partnerships and construction unit production.

Routine inspection and maintenance:

Inspection:1.vertical with or without sleeve column2.whether the positioned under the mold box spring compression rod high degree of consistency

3. Whether the screw loose gear crank4.Vibrator screw loose, because two 2.2kw, power, regular inspection

5.Check whether the electrical line failure

Maintenance:1.Daily pre-construction, oil fill within the sleeve should ensure that sleeve lubrication2.Gear oil should be replaced once every 2 months3. Work should be cleaning head, the residual material on the mold box4.Vibrator work 300 hours each, filling oil should be replaced, work 800 hours should replace the bearing

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Bag Making Machinery

Box Making Machinery

Block Making Machinery

Carton Making Machinery

Bolt Making Machinery

Cardboard Making Machinery

More>>

.jpg)